The hemmed furring channel & RC channels roll former with rolling punch is a specialized cold roll-forming machine designed to produce high-quality furring channels (hat channels) and resilient channels (RC channels) used in drywall, ceiling, and wall framing systems. This machine features an advanced hemming mechanism that creates a smooth, folded edge for improved structural integrity and safety, along with an integrated rolling punch unit for precise hole punching at specified intervals. Key Features: 1. Hemmed Edge Design – Produces furring channels with a clean, folded hem on the flanges, reducing sharp edges and enhancing durability. 2. Rolling Punch System – Automatically punches holes (round, oval, or slotted) at programmed intervals for easy fastening and seismic compliance. 3. High-Speed Production – Efficient roll-forming process with adjustable speed for consistent output. 4. Precision Roll Tooling – Customizable rolls to form various channel sizes (e.g., 7/8″, 1-1/2″, 2-1/2″) with tight tolerances. 5. Material Compatibility – Works with galvanized steel, pre-painted steel, or other metal coils (typically 20-26 gauge). 6. Automated Cutting – Hydraulic or servo-driven cutoff for accurate length control. 7. PLC Control System – User-friendly interface for easy adjustment of punching patterns, length, and speed. Applications: – Drywall Framing – Creates hat channels for ceilings and walls. – Resilient Sound Isolation – Produces RC channels for noise reduction in commercial and residential buildings. – HVAC & Electrical Support – Used for mounting ductwork and conduit. This machine ensures high efficiency, precision, and safety in manufacturing furring and resilient channels, making it ideal for metal framing manufacturers and construction material suppliers. 卷边龙骨槽钢及抗震型材专用辊压成型机(集成滚压冲孔单元)是一款专业冷弯成型设备,专用于生产吊顶隔墙系统专用的高品质卷边龙骨槽钢(帽型龙骨)与抗震型材(RC型材)。该设备采用先进的卷边工艺打造平滑折边结构,显著提升产品结构强度与安全性能,并配备集成式滚压冲孔单元,可实现精准间距的自动化冲孔作业。 核心特点: 1. 卷边结构设计 – 在龙骨翼缘形成光洁折边 – 消除锐利边缘,提升耐用性 – 增强结构整体性 2. 滚压冲孔系统 √ 按预设间距自动冲制圆孔/椭圆孔/槽孔 √ 便于快速安装固定 √ 满足抗震规范要求 3. 高效生产性能 ◆ 可调速辊压成型工艺 ◆ 生产速度最高达40米/分钟 ◆ 确保产品尺寸一致性 4. 精密成型模具 – 支持7/8″、1-1/2″、2-1/2″等规格定制 – 公差控制精度±0.2mm – 快速换模设计 5. 材料适应性 ◆ 兼容镀锌钢卷/预涂钢卷(20-26号规格) ◆ 可选配双料卷自动切换系统 ◆ 最大进料宽度300mm 6. 智能切断系统 – 液压/伺服驱动切断单元 – 长度精度±0.5mm – 支持定尺切割模式 7. PLC控制系统 √ 10英寸触摸屏人机界面 √ 可存储100组工艺参数 √ 实时监控生产数据 典型应用: – 轻钢龙骨隔墙系统:生产吊顶/墙面用帽型龙骨 – 建筑声学工程:制造商业/住宅降噪用抗震通道 – 机电安装:用于风管/线槽的支撑构件 该设备凭借其高效稳定的生产能力、精密可控的加工工艺以及智能化的操作系统,已成为金属建材制造商和建筑辅材供应商的理想选择,能充分满足现代建筑对轻钢龙骨系统日益增长的质量要求与产能需求。

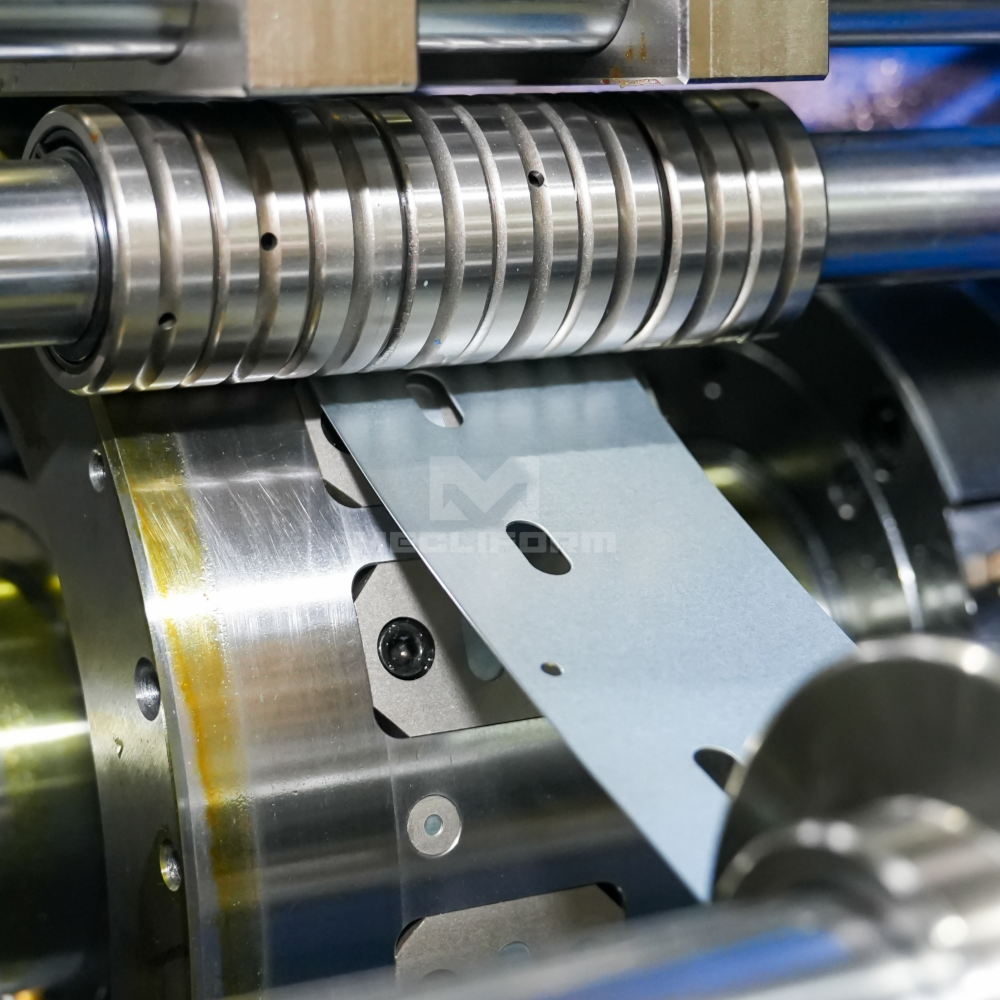

Rolling Punching unit is a process in which a rotating roller with specially designed features to create holes in a sheet of material. Roller punching is efficient, precise, and can be easily automated for high-volume production. 滚冲机是一种采用旋转辊轮在板材上冲制孔洞的加工工艺。该工艺通过特制辊轮旋转运动实现连续冲孔,具有高效精准、易于实现自动化大批量生产的特点。

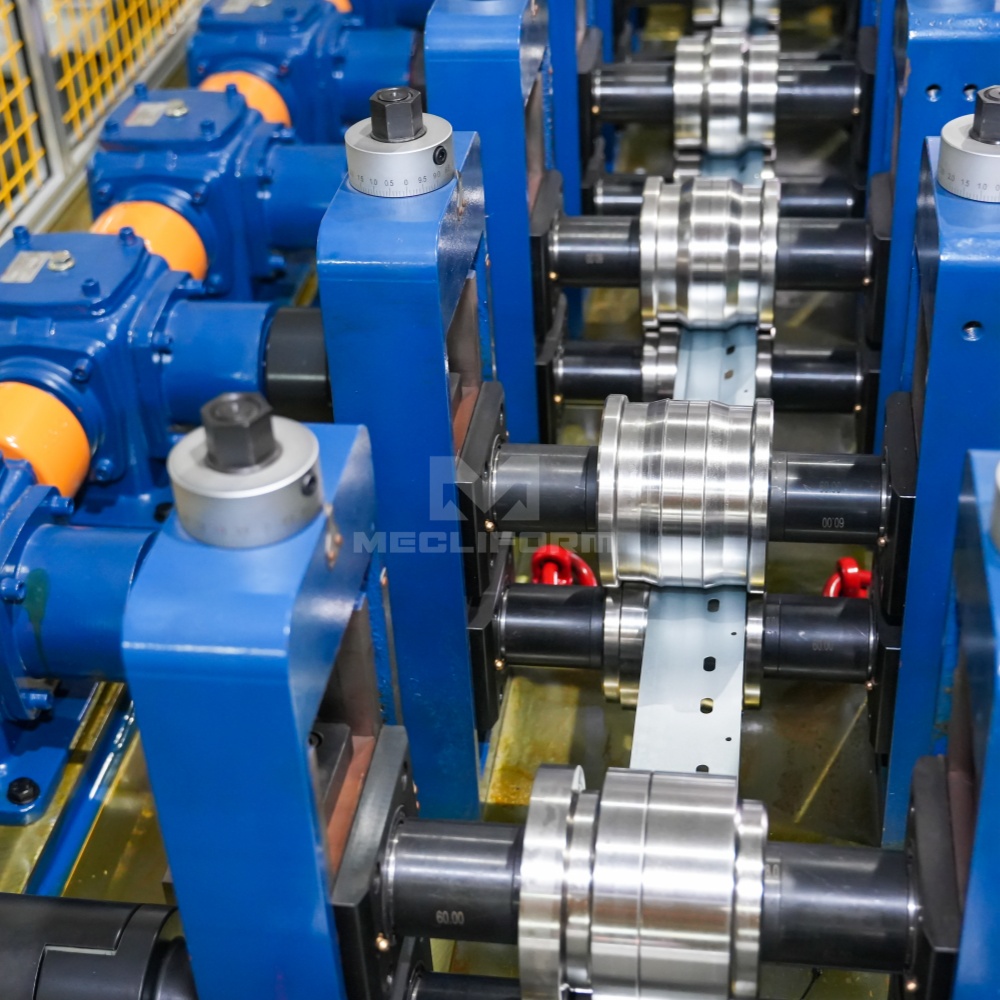

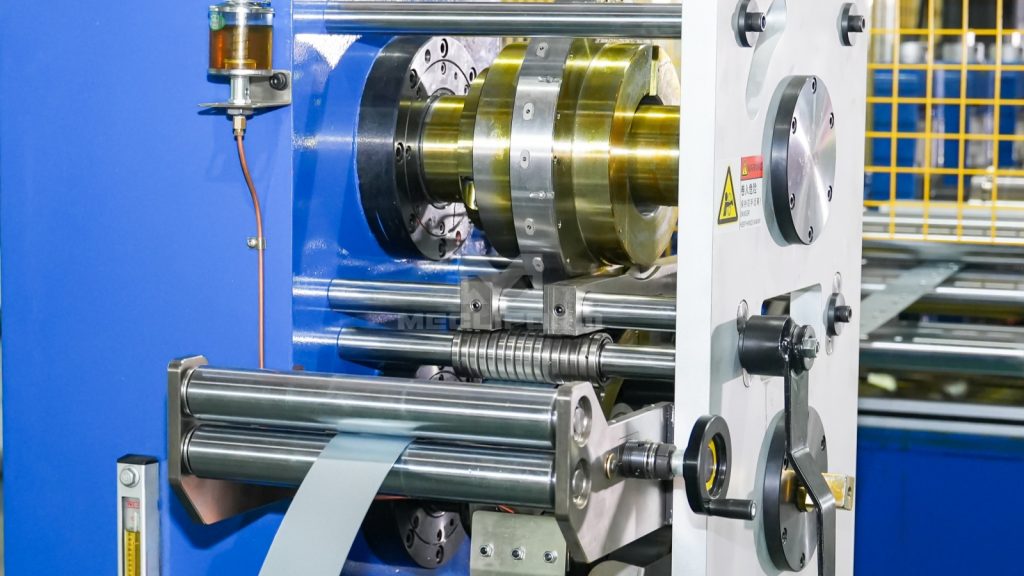

Roll former is used to create uniform, continuous bends in metal materials. It works by passing a strip of material through a series of rollers that gradually bend and form the material into its desired shape. 辊压成型机用于在金属材料上形成均匀、连续的弯曲。其工作原理是将金属带材依次通过多组轧辊,通过渐进式弯曲使材料成型为所需形状。

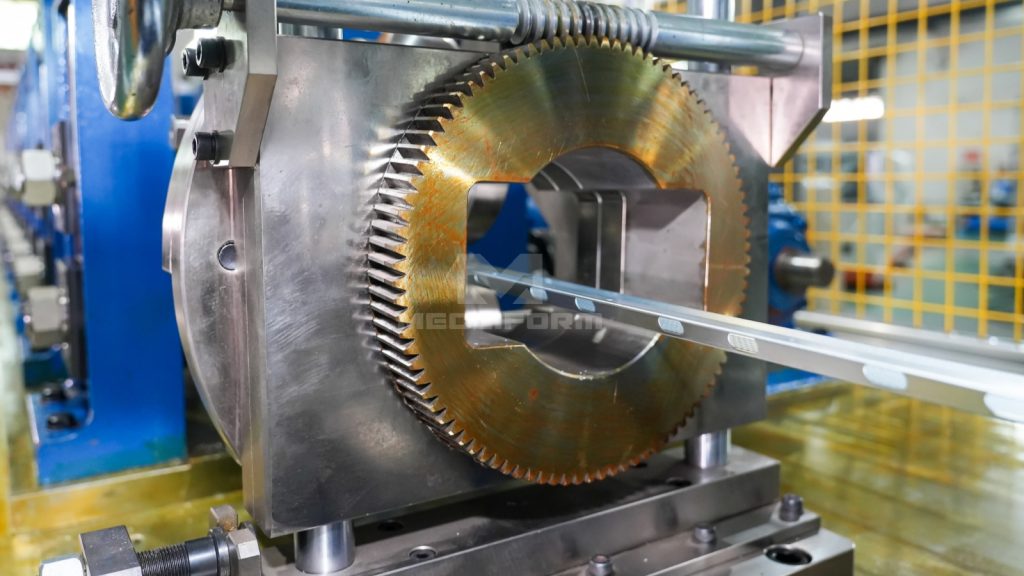

Flying cut unit is used in industrial settings to continuously cut materials without interruptions. This unit is designed to operate without pauses, allowing for efficient and fast cutting of metal sheets. 飞剪机构是一种应用于工业场景的连续切割设备,可在不停机状态下实现材料的无间断裁切。该单元通过特殊设计实现持续运行,能高效快速地对金属板材进行切割作业。