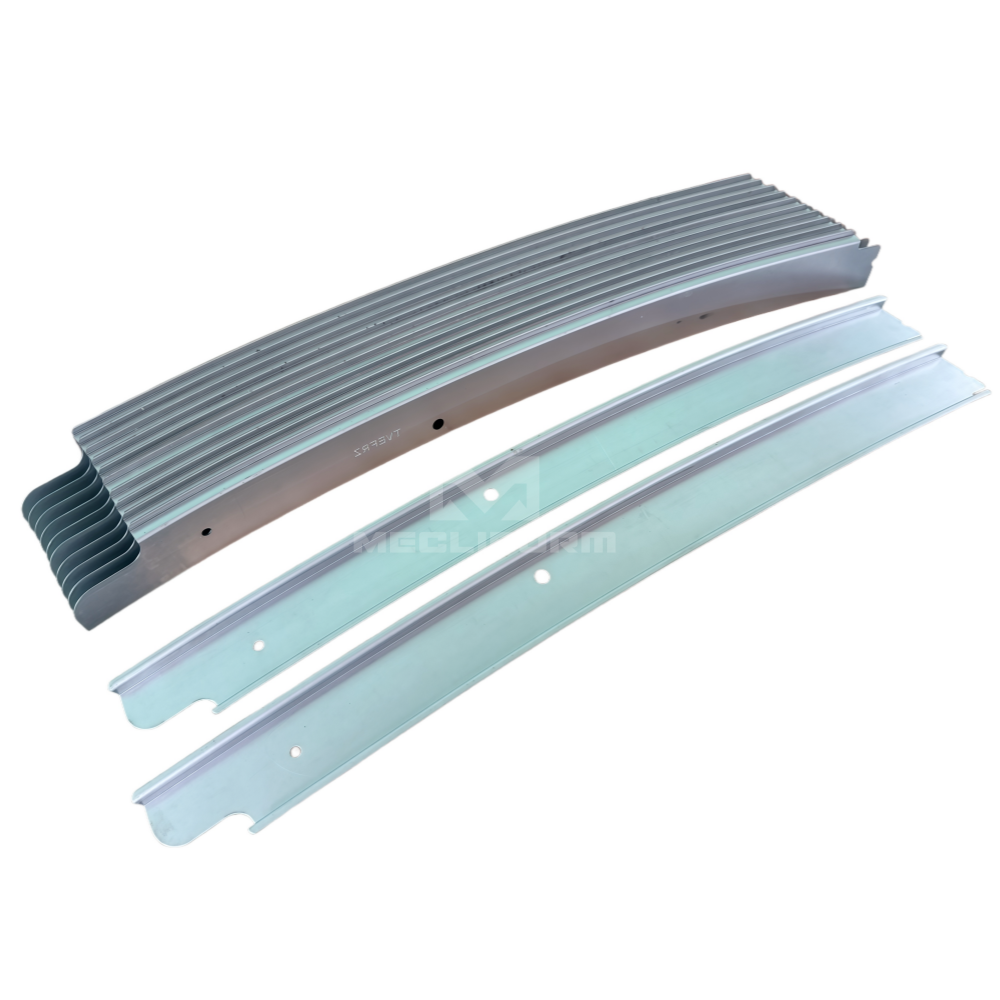

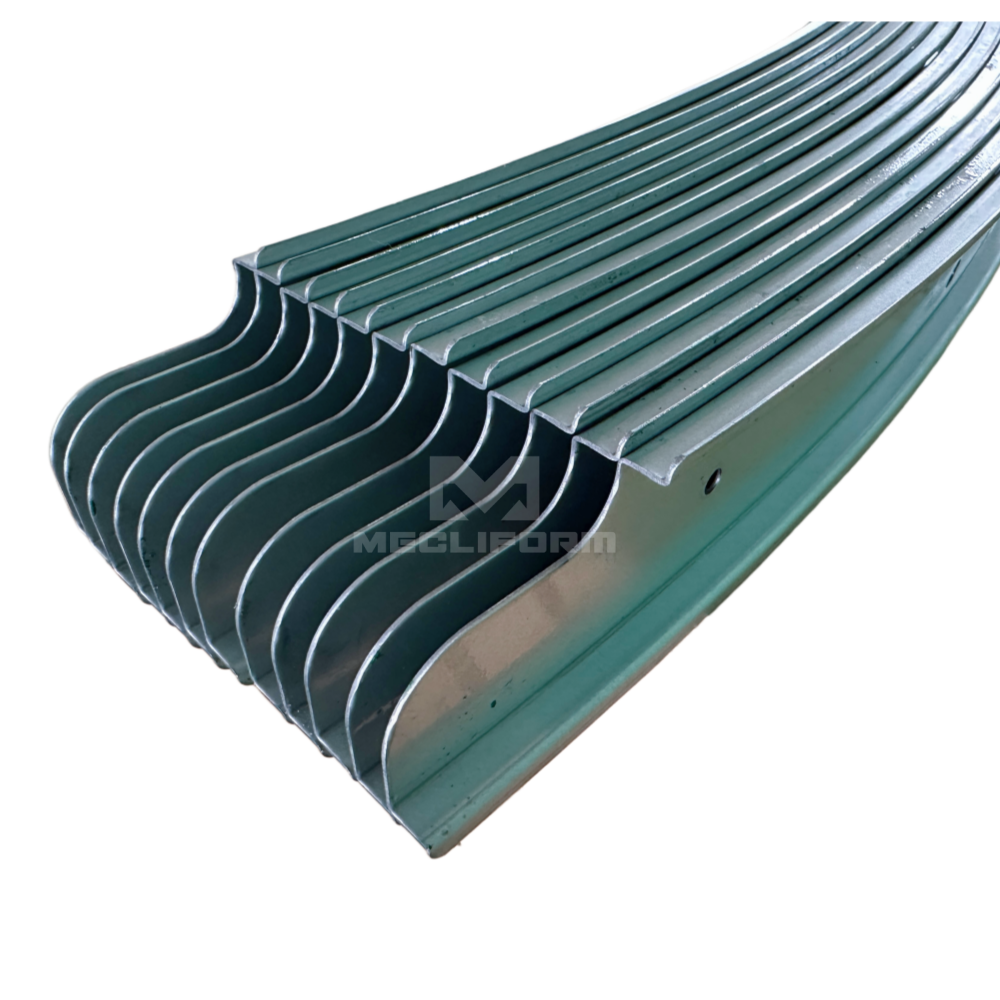

The car window guide rail roll former is a precision-engineered machine designed for the high-efficiency production of automotive window guide rails. These rails are critical components in vehicle door assemblies, ensuring smooth and stable movement of windows during operation. 汽车车窗导轨辊压成型机是一款精密设计的专用设备,用于高效生产汽车车窗导轨系统。该导轨作为车门总成的核心部件,能确保车窗升降过程中的平稳运行和精确定位。

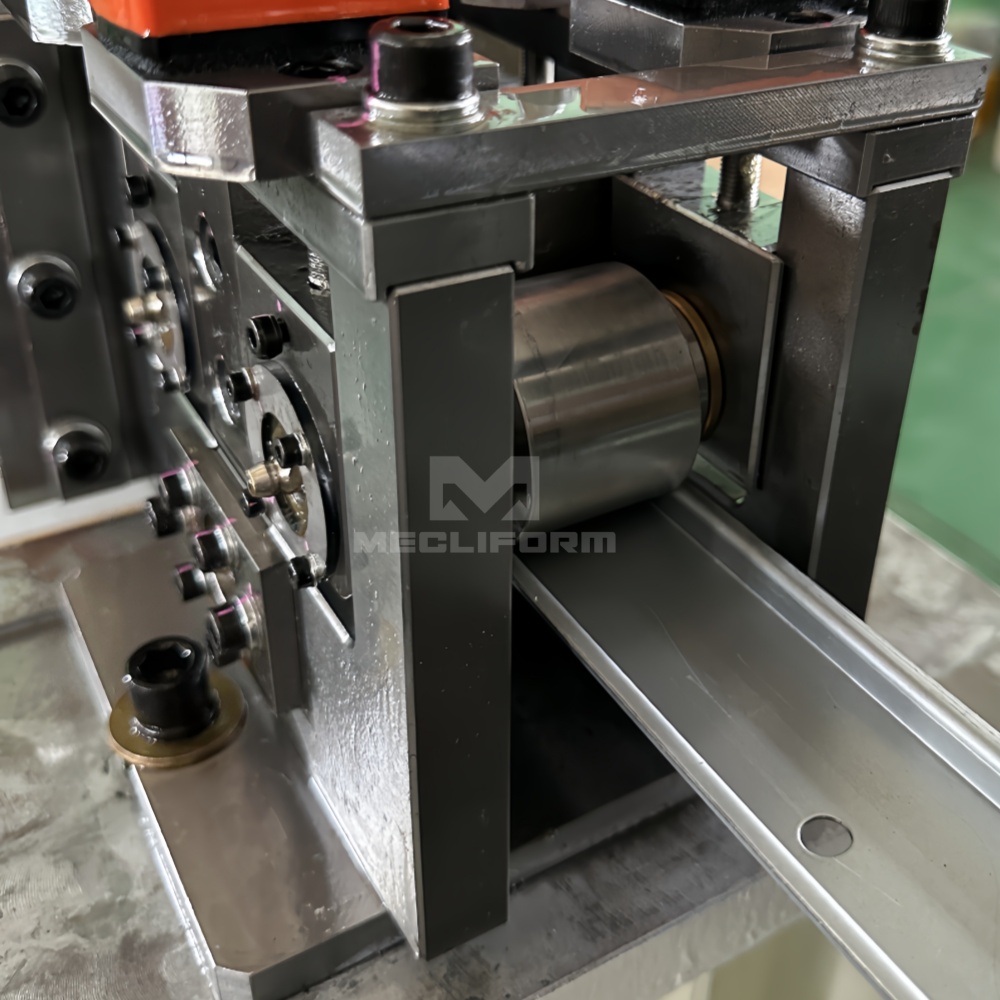

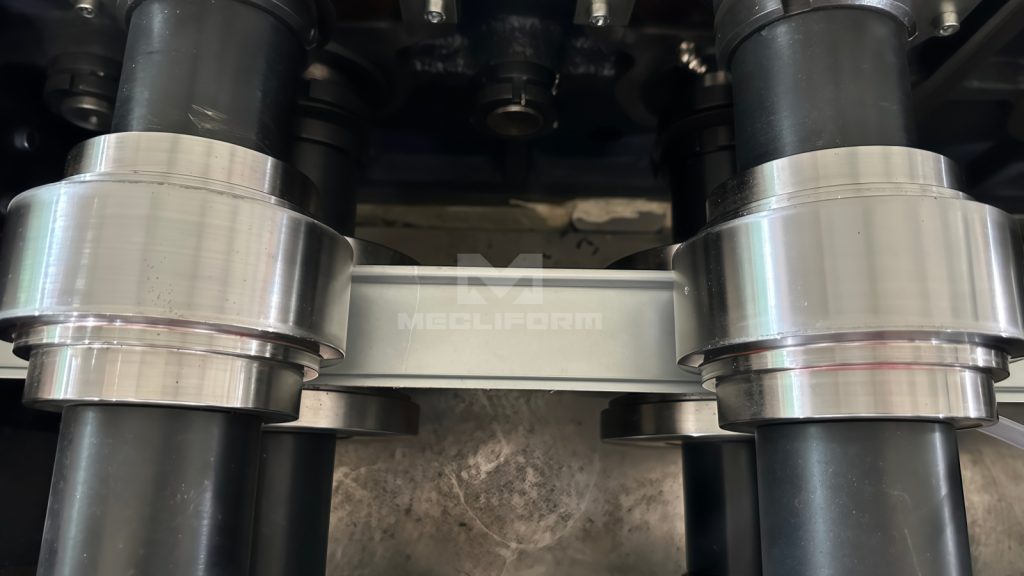

Roll former is used to create uniform, continuous bends in metal materials. It works by passing a strip of material through a series of rollers that gradually bend and form the material into its desired shape. 辊压成型机用于在金属材料上形成均匀、连续的弯曲。其工作原理是将金属带材依次通过多组轧辊,通过渐进式弯曲使材料成型为所需形状。

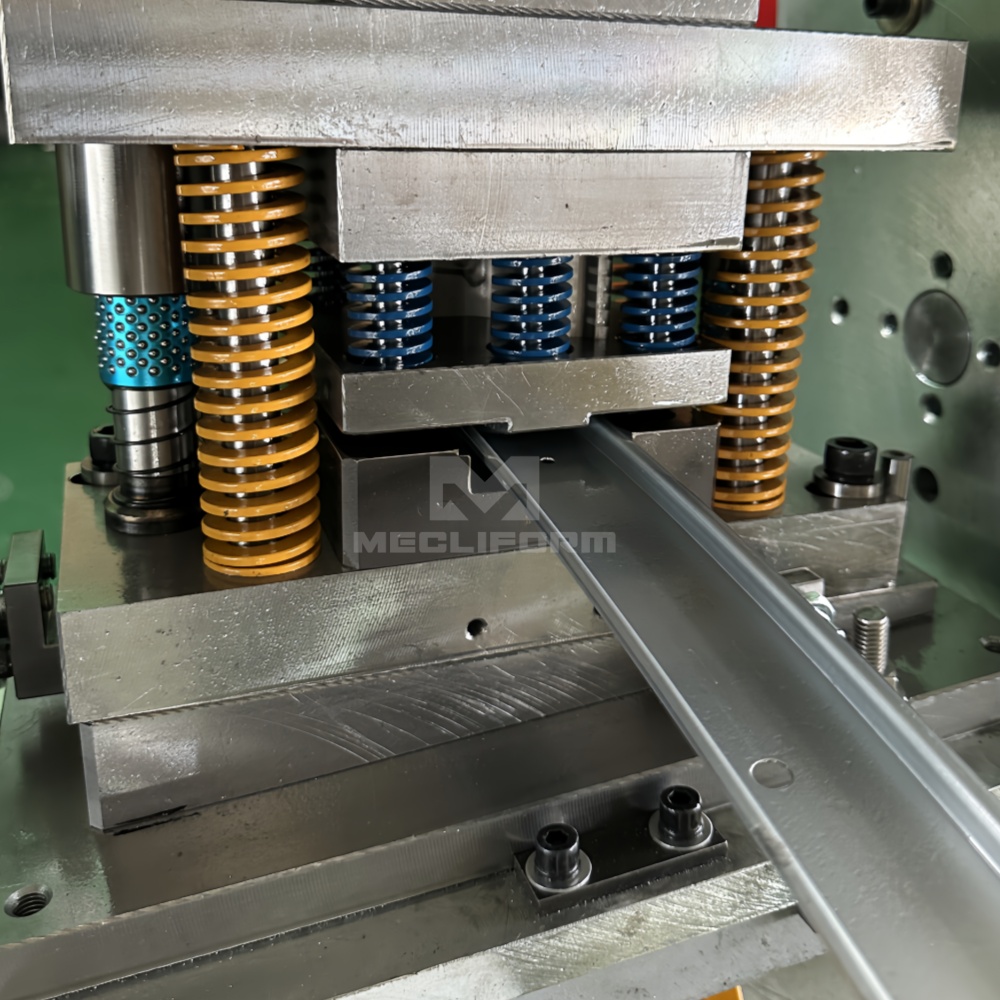

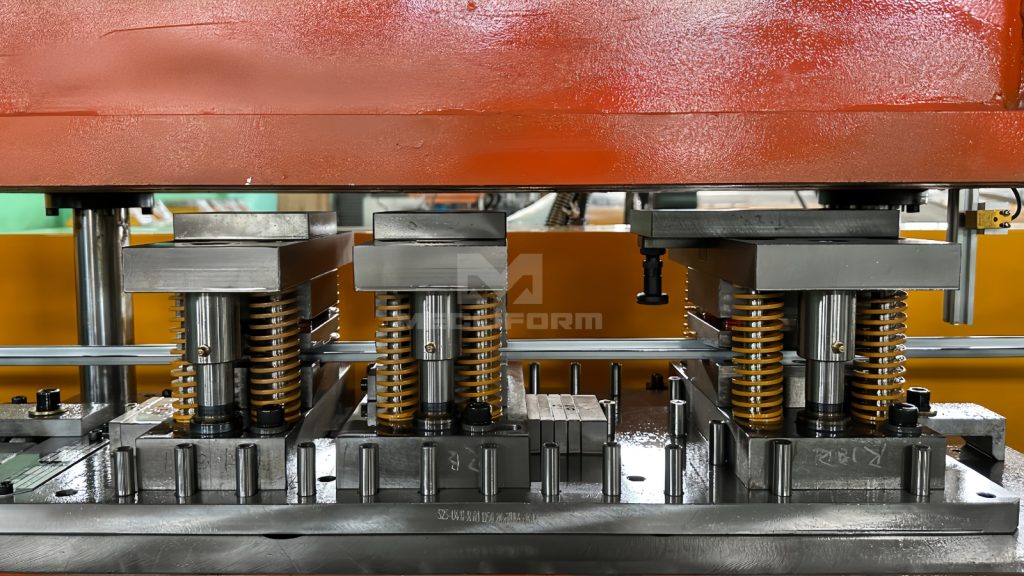

Punching unit is used to punch holes before roll forming. It typically consists of a metal tool that is propelled with force through the material to create the desired hole or shape. 冲孔装置用于在辊压成型前进行冲孔加工。该装置通常由冲孔模具构成,通过机械冲床或液压动力,从而形成所需的功能孔或特定形状。

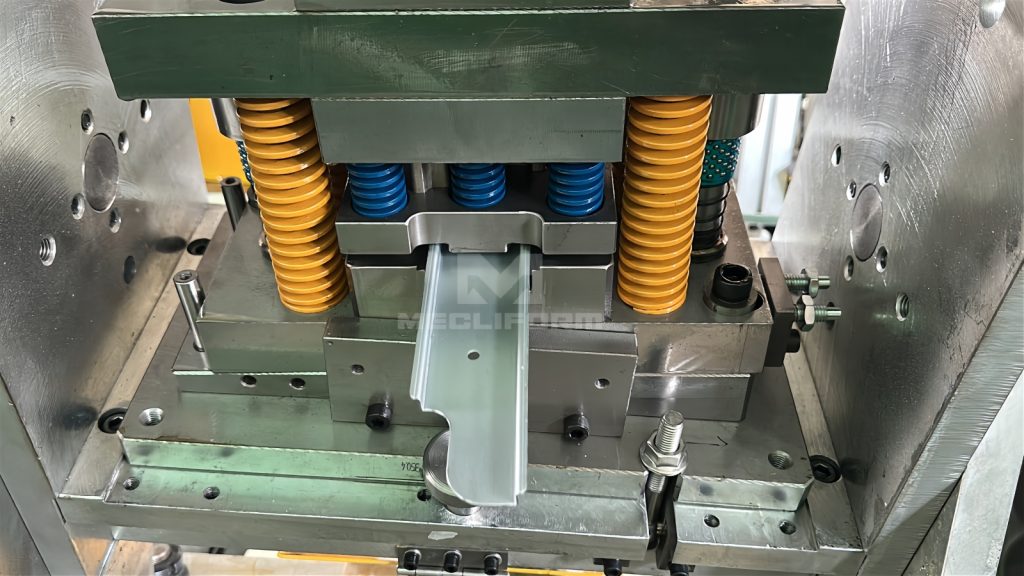

Hydraulic cutting unit is used to provide smooth and clean cuts, reducing the need for additional finishing work. It is typically operated by a control panel that allows the user to adjust the cutting speed and pressure according to the material being cut. 液压剪切机构用于实现平滑精准的切割作业,该设备通常配备智能控制面板,操作人员可根据不同材料的特性,实时调节切割速度与压力参数。