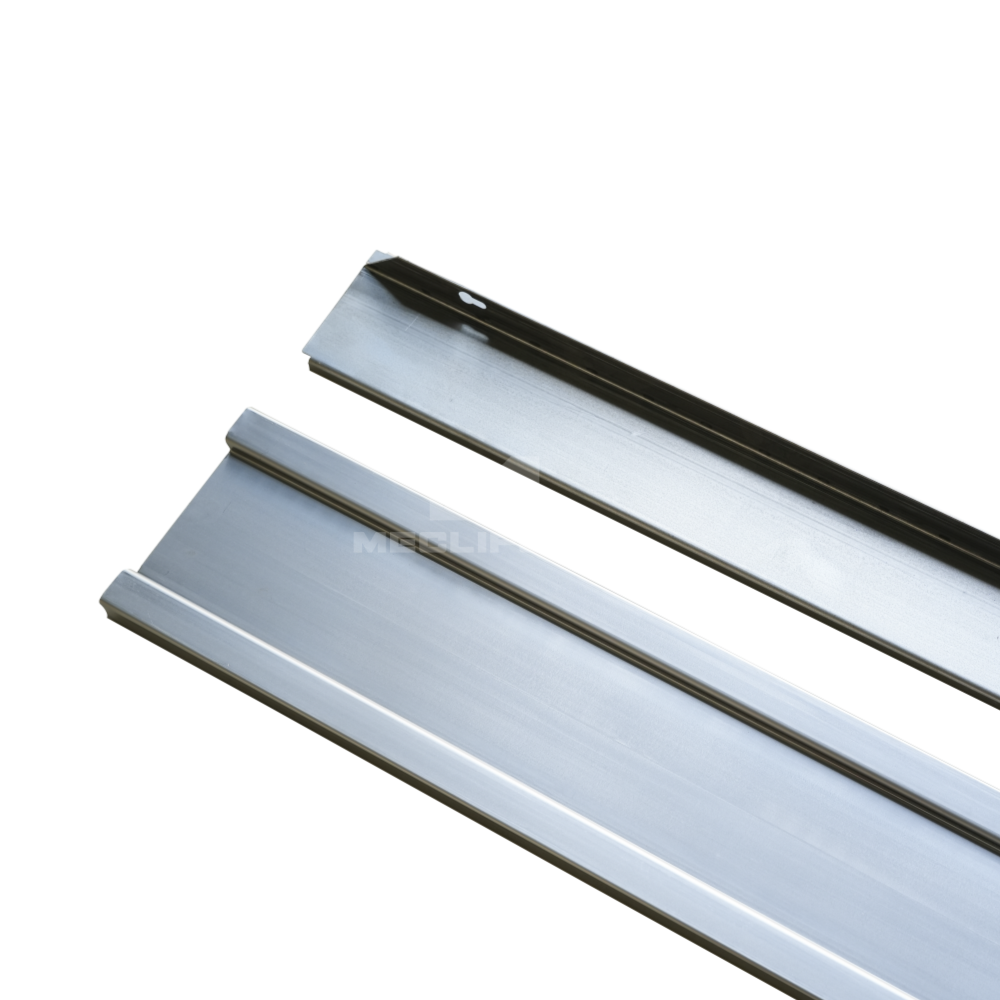

The bedside profiles roll former is a specialized cold roll-forming machine designed to manufacture high-quality metal bedside profiles used in medical, industrial, and institutional furniture. This advanced machine efficiently transforms metal coils (typically steel) into precise, durable, and uniform bedside profiles with consistent dimensions and smooth finishes. 金属床架成型机是一款专业冷弯成型设备,专为医疗、工业和公共机构家具领域制造高品质金属床沿型材。该先进设备能将钢卷(通常为钢材)高效加工成尺寸精准、经久耐用且表面光洁的标准化床沿型材。 核心特点: 1. 精密成型系统;2. 优质表面处理;3. 高效生产性能;4. 智能控制系统。典型应用: – 医用病床护栏系统 – 养老护理设施家具 – 实验室工作台边沿 – 工业操作台防护边 该设备通过精密的冷弯成型技术和智能控制系统,确保生产的床沿型材兼具结构强度与美观度,完全满足医疗家具对卫生安全性和耐用性的严苛要求。其模块化设计可快速切换不同型材截面,是医疗家具制造商提升产品竞争力的理想选择。

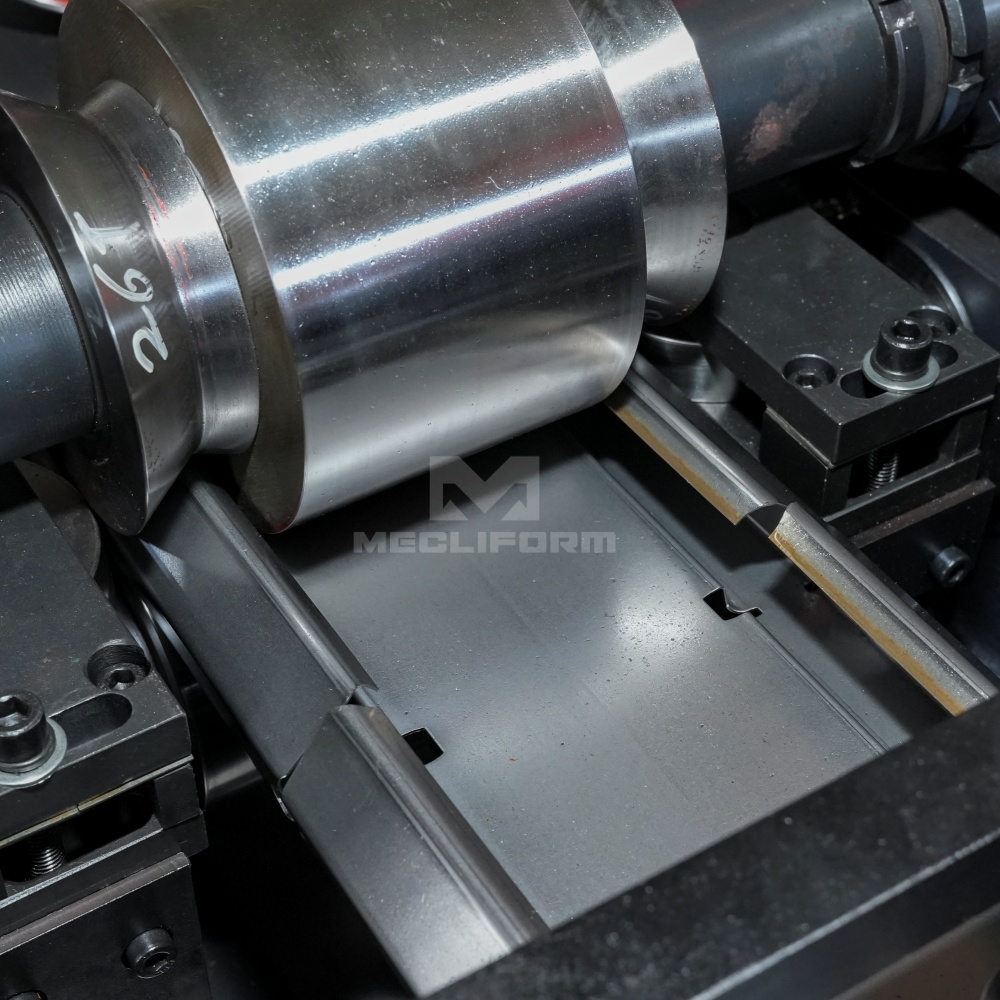

Punching unit is used to punch holes before roll forming. It typically consists of a metal tool that is propelled with force through the material to create the desired hole or shape. 冲孔装置用于在辊压成型前进行冲孔加工。该装置通常由冲孔模具构成,通过机械冲床或液压动力,从而形成所需的功能孔或特定形状。

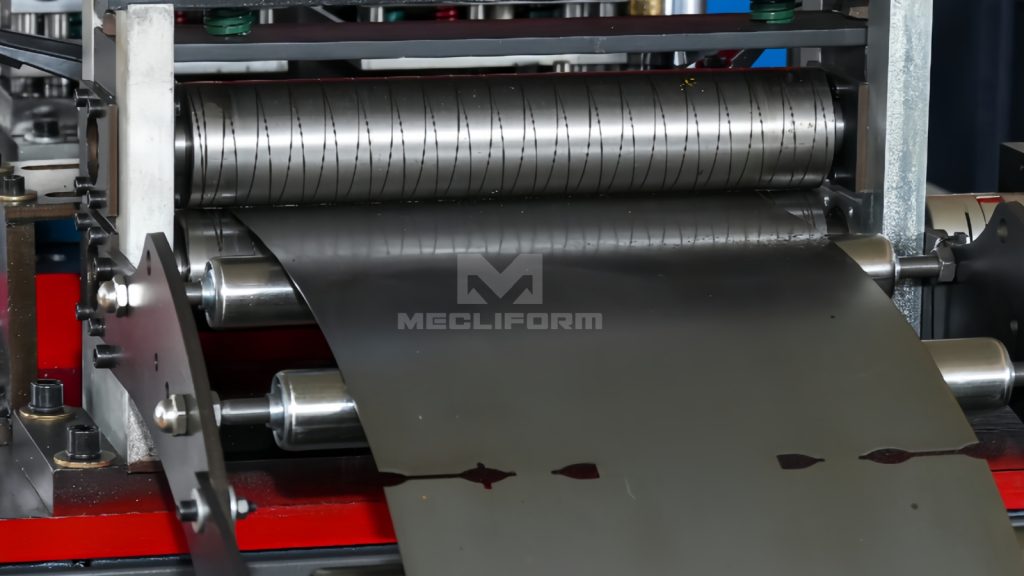

Roll former is used to create uniform, continuous bends in metal materials. It works by passing a strip of material through a series of rollers that gradually bend and form the material into its desired shape. 辊压成型机用于在金属材料上形成均匀、连续的弯曲。其工作原理是将金属带材依次通过多组轧辊,通过渐进式弯曲使材料成型为所需形状。

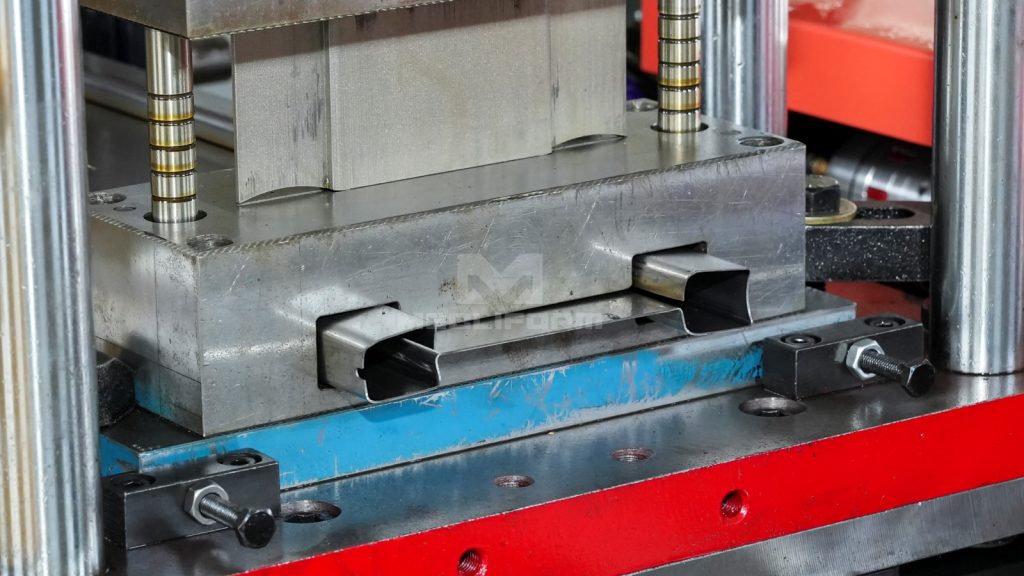

Hydraulic cutting unit is used to provide smooth and clean cuts, reducing the need for additional finishing work. It is typically operated by a control panel that allows the user to adjust the cutting speed and pressure according to the material being cut. 液压剪切机构用于实现平滑精准的切割作业,该设备通常配备智能控制面板,操作人员可根据不同材料的特性,实时调节切割速度与压力参数。