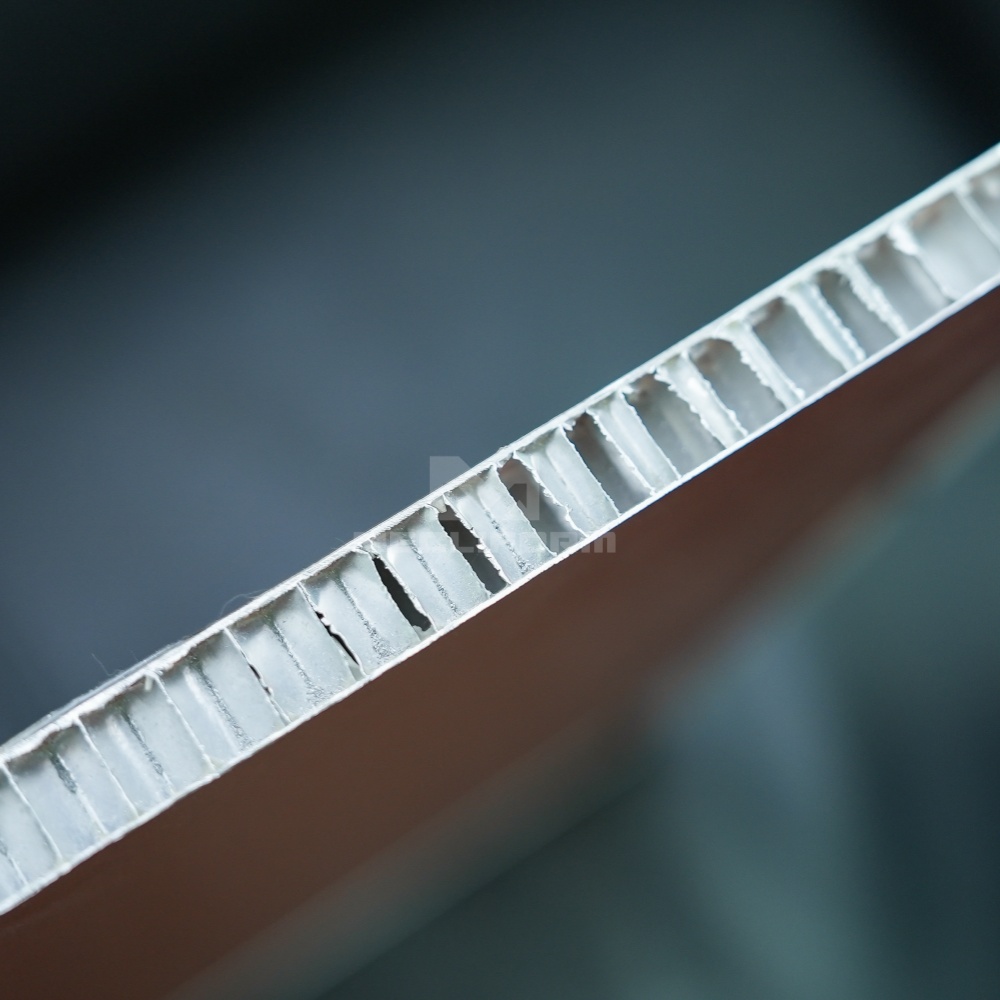

Our ceiling tile machines are capable of producing a wide range of ceiling tile profiles, including standard and custom designs, traditional tiles and honeycomb core types. These machines are equipped with advanced features for cutting, forming, and finishing tiles with precision and efficiency. 我们的天花板板材生产线可生产多种类型的吊顶型材,包括标准款与定制款、传统平板型及蜂窝芯结构型。设备配备先进的切割、成型和精加工系统,确保高效精准地完成各类板材的加工生产。

Notching unit is used to notch before roll forming. It typically consists of a notching tool (left and right) that is propelled with force through the material to create the desired notch for further corner bending. 前冲机构用于在辊压成型前进行缺口冲切加工。该装置通常由左右对称的冲缺模具组成,通过液压冲压形成预设缺口,为后续转角折弯工序做准备。

Roll former is used to create uniform, continuous bends in metal materials. It works by passing a strip of material through a series of rollers that gradually bend and form the material into its desired shape. 辊压成型机用于在金属材料上加工出均匀连续的折弯形状。其工作原理是将金属带材依次通过多组轧辊,经过渐进式弯曲变形,最终成型为所需截面形状。

Servo bending unit utilizes servo motor technology to control the bending process with precision and consistency. This unit is equipped with adjustable settings and easily programmable features, allowing for a wide range of bending angles and shapes to be achieved. 伺服折弯机构采用全伺服电机驱动技术,可通过一次定位精准稳定地控制折弯加工过程。该单元配备可调式参数设定和简易编程功能,能够实现多种折弯角度和异形件的加工需求。

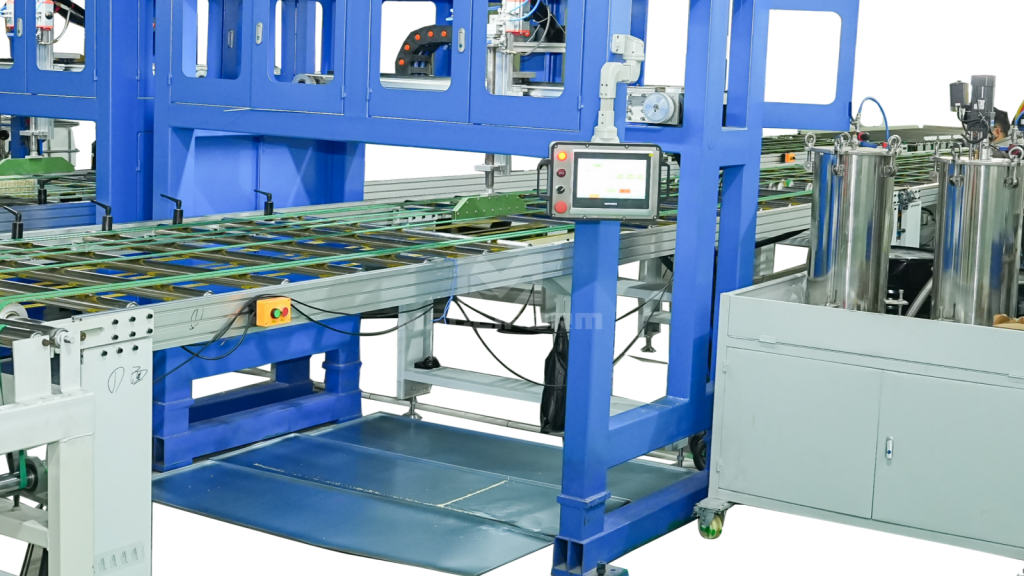

Auto assembly unit consists of a series of equipment, including glue sprayer, alignment unit, combination unit, turn-over unit, auto stacking unit, and cold presses. 自动组装机构由多台设备集成构成,包含淋胶机、定位装置、合板机构、翻转机构、自动堆垛装置及冷压机等成套设备。