Our ceiling tile machines are capable of producing a wide range of ceiling tile profiles, including standard and custom designs. These machines are equipped with advanced features for cutting, forming, and finishing tiles with precision and efficiency. 我们的天花板板材生产线设备能够生产多种类型的吊顶板型材,包括标准规格和定制设计。这些设备配备先进的切割、成型和精加工功能,可确保高效精准地完成板材加工。

Perforation unit is used to punch holes before roll forming. It typically consists of perforation tool that is propelled with force through the material to create the desired holes. 冲孔装置用于在成型前进行冲孔作业。该装置由冲孔模具组成,通过强力冲压穿透材料,从而形成所需的孔。

Corner cutting unit is used to cut four corners of strips and cut into length before bending, one stroke for one piece to avoid deviation stack-up (cumulative error). 切角机构用于在折弯前对带材进行四角切割及定长裁切,采用单次冲裁成型工艺,有效避免偏差叠加(累积误差)。

Turn-over unit is used to turn another side of pre-cut sheet, and next step it will be carried by manipulator (pneumatic suction type) for bending. 翻转机构用于将预切板材翻转至另一面,随后由机械手(气动吸附式)抓取并移送至成型工序。

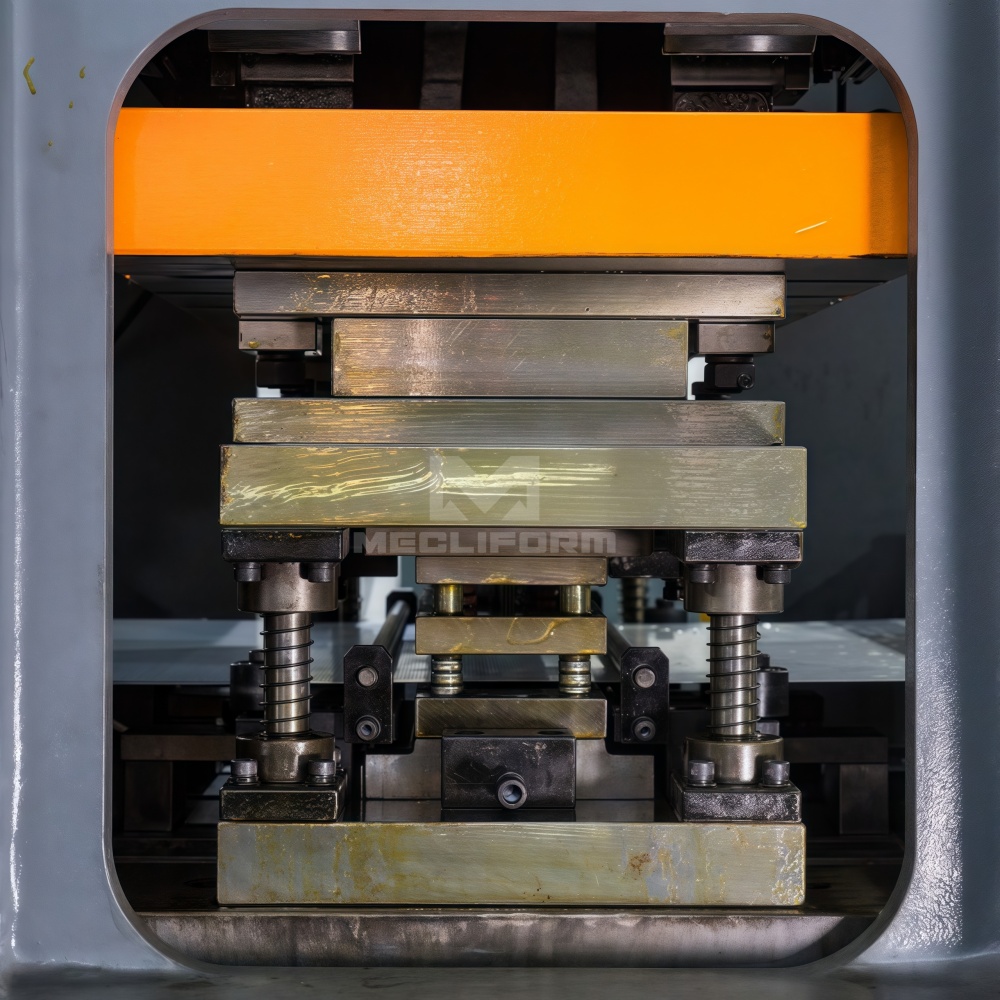

Hydraulic Bending unit is used for bending the strips for ceiling tiles, clip-in type or lay-in type. 液压成型机构专用于天花板板材(明格或暗格)的板材折弯加工。