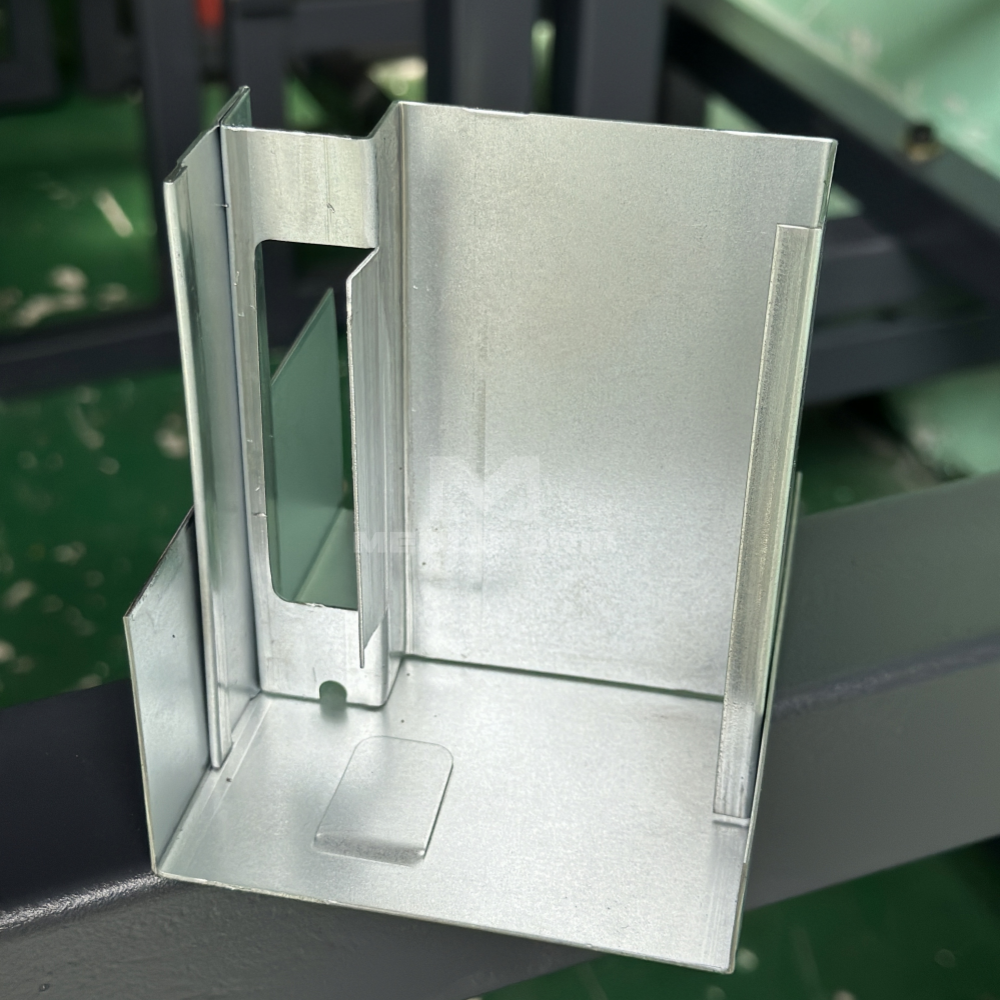

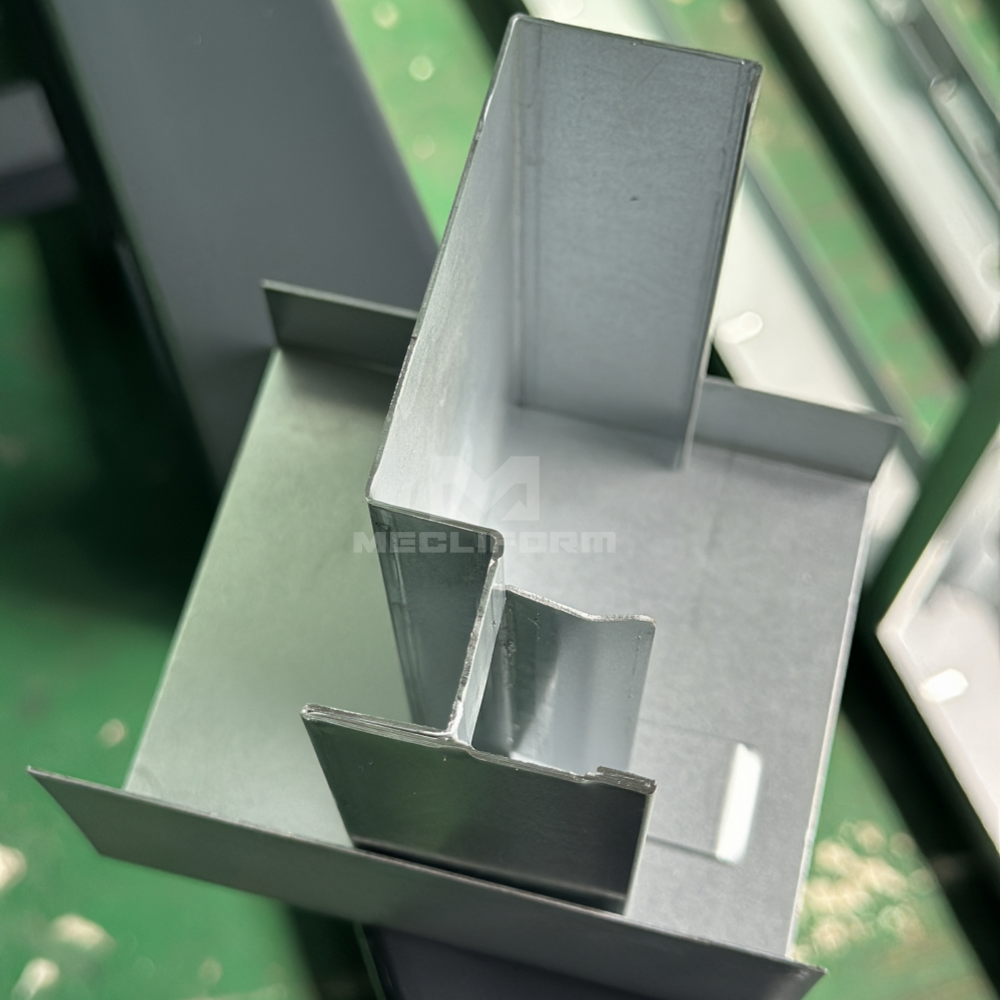

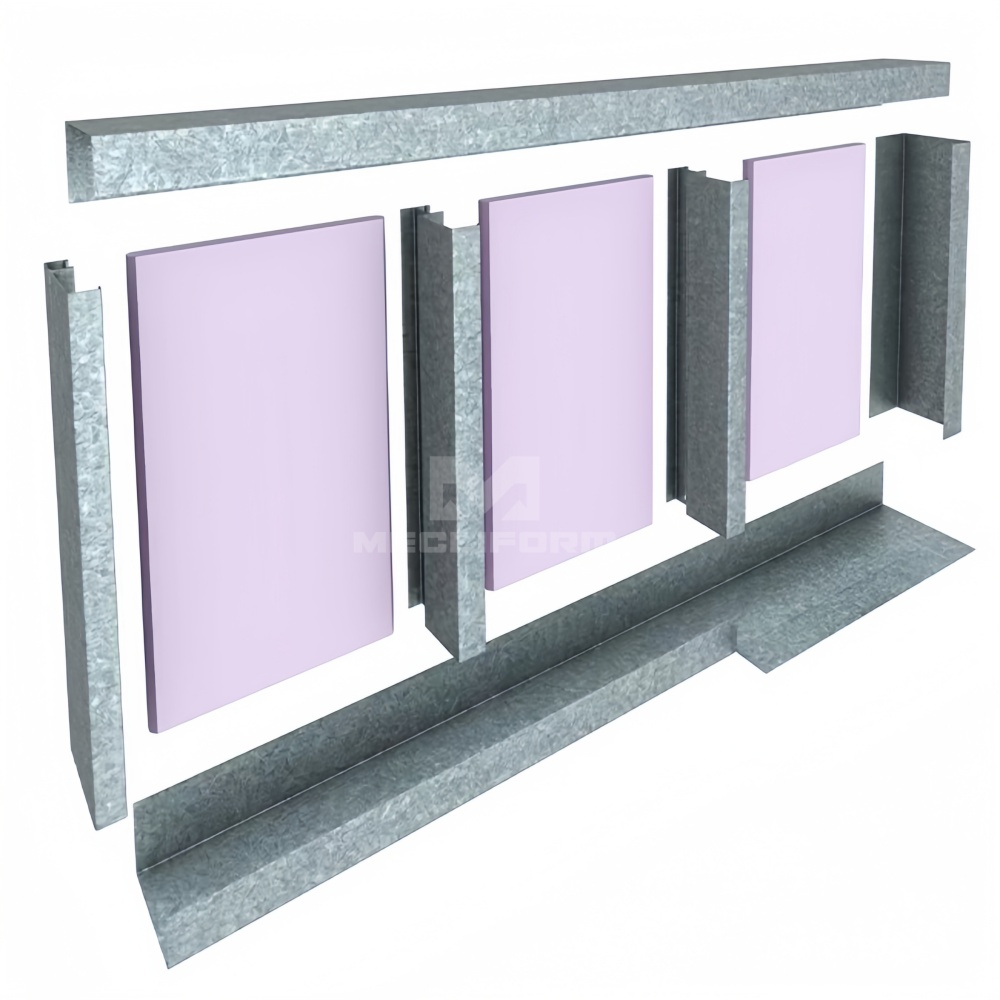

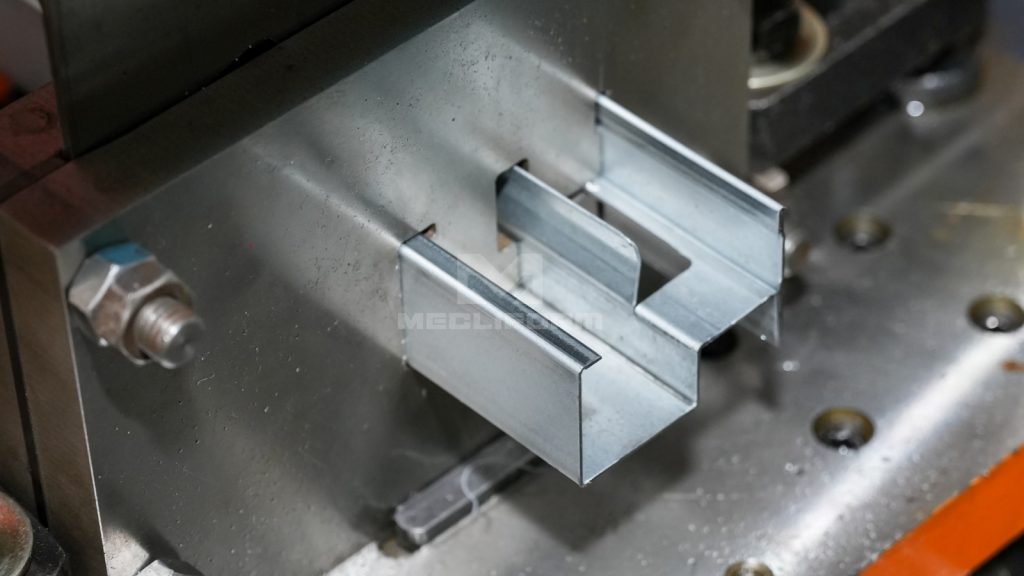

Shaftwall CT Stud is a type of metal stud used in the construction of shaftwalls, which are vertical enclosures in buildings that house plumbing, electrical, and ventilation systems. The CT Stud is specifically designed for use in shaftwall assemblies to provide support and stability for the enclosure. The Shaftwall CT Stud is made of galvanized steel, which provides rust and corrosion resistance, making it durable and long-lasting. It features a unique C-shaped design that allows for easy installation and bolting of the stud to the floor and ceiling, providing a secure connection for the shaftwall system. The CT Stud is also designed with pre-punched holes for easy attachment of drywall or other finishing materials, making it a versatile and efficient choice for shaftwall construction. Its lightweight and compact design make it easy to transport and handle on the job site, resulting in faster and more efficient installation. Overall, the Shaftwall CT Stud is a reliable and durable metal stud option for creating strong and stable shaftwalls in commercial and residential buildings. 竖井墙专用CT龙骨是一种用于建筑竖井墙结构的金属立筋。竖井墙作为建筑中容纳管道、电气及通风系统的垂直围护结构,其专用CT龙骨经过特殊设计,可为竖井墙系统提供稳固的支撑保障。该产品具有以下显著特点: 1. 材质特性 – 采用镀锌钢材制造 – 具备优异的防锈防腐性能 – 结构坚固耐用 2. 结构设计 √ 独特的C型截面设计 √ 便于与楼板/天花进行螺栓固定 √ 预冲孔设计方便石膏板等饰面材料安装 3. 施工优势 – 轻量化紧凑型设计,便于运输及现场安装,显著提升施工效率 (应用价值)。作为竖井墙系统的核心支撑构件,CT龙骨凭借其可靠的性能表现,已成为商业及住宅建筑中构建高强度竖井墙的首选解决方案。其创新设计既确保了竖井结构的稳定性,又大幅提升了施工便捷性,完美兼顾了工程质量与施工效率的双重需求。

Punching unit is used to punch holes before roll forming. It typically consists of a metal tool that is propelled with force through the material to create the desired hole or shape. 冲孔装置用于在辊压成型前进行冲孔加工。该装置通常由冲孔模具构成,通过机械冲床或液压动力,从而形成所需的功能孔或特定形状。

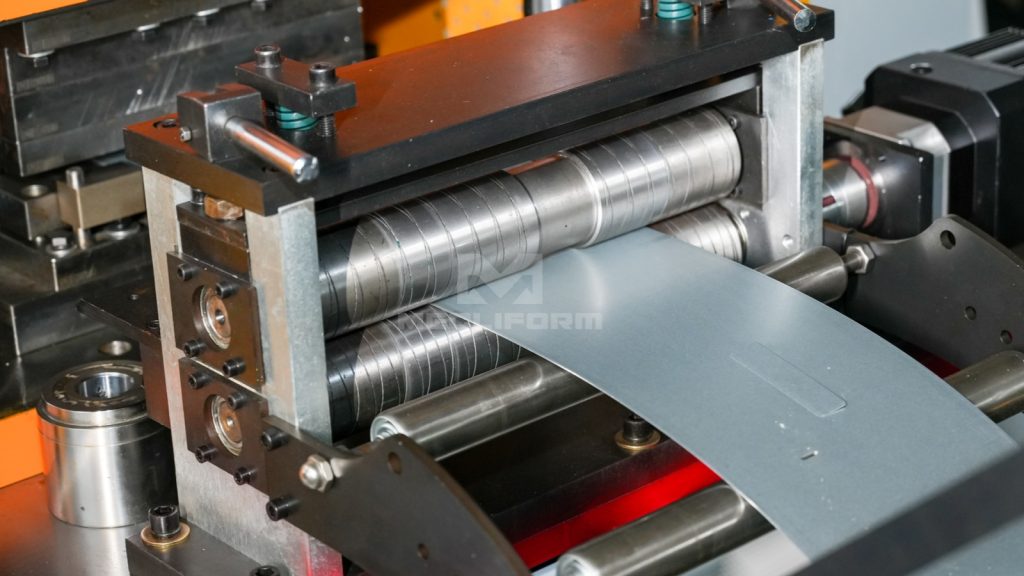

Roll former is used to create uniform, continuous bends in metal materials. It works by passing a strip of material through a series of rollers that gradually bend and form the material into its desired shape. 辊压成型机用于在金属材料上形成均匀、连续的弯曲。其工作原理是将金属带材依次通过多组轧辊,通过渐进式弯曲使材料成型为所需形状。

Hydraulic cutting unit is used to provide smooth and clean cuts, reducing the need for additional finishing work. It is typically operated by a control panel that allows the user to adjust the cutting speed and pressure according to the material being cut. 液压剪切机构用于实现平滑精准的切割作业,该设备通常配备智能控制面板,操作人员可根据不同材料的特性,实时调节切割速度与压力参数。